The Challenge: Traditional Quality Inspections

In a leading automotive manufacturing facility, the quality assurance (QA) team has been responsible for manually inspecting newly manufactured vehicles to identify dents and scratches. This process, while critical to ensuring high-quality standards, has several limitations.

- Manual Inspection Process:QA team members visually inspect the exterior of each vehicle, marking any detected defects.

- Challenges:Time-consuming and labor-intensive.

- Inconsistent results due to human error and subjective judgment. ○ Limited documentation, leading to delayed feedback for production teams.

- Difficulty in detecting minor or subtle imperfections, which often go unnoticed.

With the increasing volume of vehicles being produced and the need for precision, the current inspection process became a bottleneck in the production line, affecting both speed and accuracy.

The Vision: Automating the Detection Process

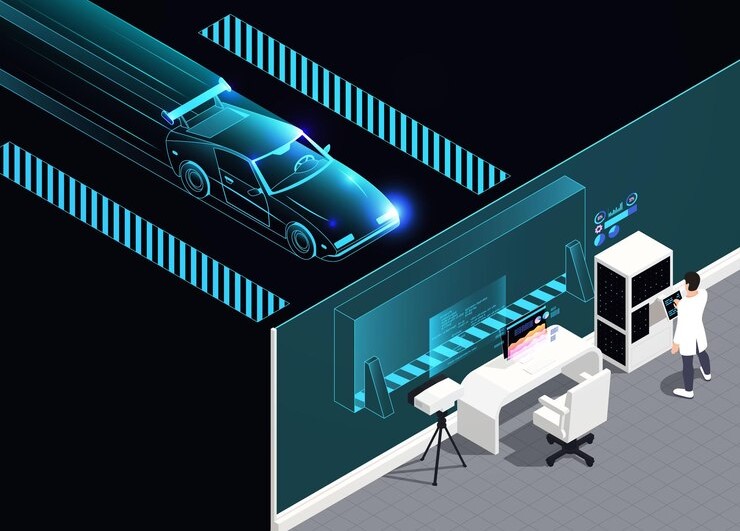

Pixl was tasked with proving the feasibility of automating the dent and scratch detection process. The goal was clear: to implement a system that uses high-resolution cameras and AI-driven detection techniques to automate quality inspections on the production line.

Solution: Automated Dent and Scratch Detection System

Pixl introduced an innovative, AI-based solution designed to revolutionize the way vehicle quality inspections are carried out.

High-Resolution Cameras:

- Positioned strategically along the production line, these cameras cover all sides of the vehicle.

- Challenges:Time-consuming and labor-intensive.

- The cameras capture minute details and surface defects at high speed, ensuring no imperfection goes unnoticed as the vehicle moves along the conveyor belt.

AI-Based Image Processing:

- The captured images are processed by advanced AI algorithms designed to detect and classify defects into specific categories such as dents or scratches.

- The system analyzes the images in real-time, providing precise feedback to the QA team, including the exact location and severity of each defect.

Automated Reporting:

- Real-time reports are generated, complete with image evidence and detailed defect locations.

- These reports are automatically shared with the QA team, significantly reducing the time needed for manual documentation and ensuring faster, more informed decision-making.

The Process: Phases of Implementation

The implementation of this automated system followed a structured and phased approach to ensure feasibility and smooth integration into the production environment:

- 1. Discovery Phase:Understanding the current process, identifying key pain points, and setting project goals.

- 2. Model and Algorithm Development:Developing AI models and algorithms to accurately detect and classify dents and scratches on vehicle surfaces.

- 3. Model Training with Sample Datasets:Training the AI models using sample datasets to improve the system's accuracy and ability to identify defects of various sizes and types.

- 4. Site Visit and Testing:Conducting site visits to test the system in real-world conditions, ensuring its ability to handle high-speed production environments and deliver real-time results.

The Benefits: Unlocking the Future of Quality Control

The automated system is poised to deliver a range of significant benefits:

- Increased Accuracy:The AI system eliminates inconsistencies caused by human error, providing more reliable and consistent detection of defects.

- Faster Inspections:Real-time, automated detection reduces inspection time, allowing for quicker feedback to production teams and minimizing production delays.

- Enhanced Documentation:Automated reports ensure comprehensive records, improving traceability and reducing the risk of missing defects.

- Improved Quality Control:The precision of AI-driven defect detection ensures that even the smallest imperfections are identified and addressed, leading to higher-quality vehicles.

Key Takeaways

Pixl’ automated dent and scratch detection system offers a glimpse into the future of quality control in automotive manufacturing. By leveraging AI and high-resolution cameras, Pixl is paving the way for faster, more accurate, and cost-effective inspections, making traditional manual inspection methods a thing of the past.