Objective: Enhancing Security and Access Control Through Automation

As organizations become more complex, security demands in sensitive areas, like corporate and bank facilities, rise. Traditionally, many institutions used stickers or permits to control vehicle entry. But, as operations grow and more vehicles enter a facility, manual processes can become slow and insecure.

A leading bank faced these challenges. They wanted to replace their old, sticker-based vehicle access system. They sought an automated, efficient solution.

Streamline vehicle entry. Enhance security. Reduce the workload on security staff.

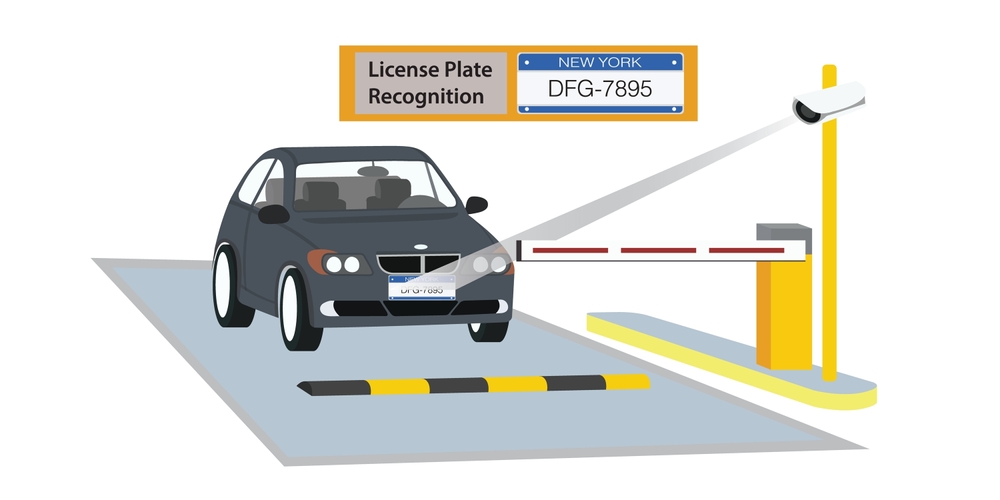

The bank decided to use an AI-based number plate recognition system. It would integrate with their existing control room infrastructure. The goal was to allow automated vehicle access. It aimed to cut reliance on physical permits. It also sought to enable real-time monitoring and data management.

Solution: AI-Based Number Plate Recognition System

The AI-based number plate recognition system uses advanced algorithms. It reads vehicle license plates and grants or denies access based on set controls. This system eliminates the need for physical stickers on vehicles. It also reduces human involvement in routine security operations.

Key Components of the Solution:

AI-Driven License Plate Recognition Technology: The system uses an AI algorithm. It can accurately read number plates in various conditions. The AI models are trained on thousands of images. They can recognize number plates despite changes in light, angle, or weather. The system can process alphanumeric characters and different vehicle types. This ensures high accuracy and reliability.

The system was API integrated into the bank's control room. It lets data flow from the number plate system to the control room's monitor. The control room can monitor vehicles in real-time. It can also receive alerts about security events. And, it has a full view of the vehicle inflow at any moment.

Automated Access Control: The system checks a vehicle's license plate against a database of authorized users. If the vehicle is registered in the system, access is granted automatically. Unauthorized vehicles trigger an alert, enabling the security team to take appropriate action. This automated process removes the need for manual checks. It ensures vehicles can enter the premises quickly and efficiently.

Data Management and Analytics: The system monitors vehicles in real-time. It also analyzes data. It can track vehicle movements, log entry and exit times, and report on traffic patterns. These insights can help optimize security protocols and vehicle management in the future.

Benefits of AI-Based Number Plate Recognition System:

Enhanced Security:

The AI system ensures only authorized vehicles access the premises. This greatly reduces the risk of unauthorized entries. The bank's security team can quickly respond to threats. Automated recognition and real-time monitoring boost the facility's safety.

The system can quickly detect stolen or unregistered vehicles. The control room can flag and block them before they enter the premises. This is vital in high-security places like banks. There, protecting assets and people is critical.

Increased Efficiency:

The system automates vehicle access control. It reduces delays from manual checks. Employees and visitors no longer need to wait in long lines for security personnel to verify their entry permits. Instead, the system recognizes the vehicle as it approaches. If authorized, it grants access immediately.

For banks that manage many vehicles daily, this boost means smoother operations. It improves the experience for employees and customers alike. The system can handle hundreds of vehicles daily. It won't lose accuracy or speed, so operations will run without interruption.

Cost Reduction:

Switching from physical stickers and manual checks to an automated system cuts costs. It removes the need to maintain permits, hire security, and manage badges. Also, the AI system needs less maintenance than traditional access systems. So, it saves money in the long run.

Comprehensive Monitoring and Control:

The system's real-time data gives the control room staff of the bank an unprecedented level of control over vehicle access. Live vehicle tracking lets security staff quickly spot and fix issues. Also, the system stores all vehicle entry and exit data. This enables a detailed audit trail for future reference.

This monitoring is crucial in high-security environments. Even a small breach could have serious consequences. Control room staff can manage access remotely. This ensures control of vehicle entry during off-hours or emergencies.

Scalability and Flexibility:

The AI number plate recognition system is scalable. It can easily adapt to future needs. As the bank grows or security needs change, the system can be upgraded. It can fit more vehicles or work with other security, like facial recognition or RFID access.

The system's flexibility allows its use at multiple locations. It offers a standardized solution for all the bank's facilities. This adaptability is vital for organizations. They want to keep security standards the same across different sites.

Outcome: Improved Security, Efficiency, and Control

After the bank put in an AI-based number plate recognition system, it saw big gains in security and efficiency. The key outcomes include:Streamlined Access Control: The automated system sped up vehicle processing. This reduced congestion at entry points and eliminated the need for physical stickers. Authorized vehicles gained instant access. Unauthorized ones were flagged for review.

Enhanced Real-Time Monitoring: Control room staff now see all vehicle activity at the site. Real-time data let them better monitor traffic and respond to threats. It also ensured only authorized vehicles could enter.

Increased Security: The AI number plate system reduced the risk of unauthorized access. The bank tightened its security with automated checks for unauthorized vehicles. This enhanced the overall safety of the premises.

Optimized Resource Allocation: The bank automated vehicle access control. It reduced the workload on security personnel. This let them focus on strategic tasks, like monitoring cameras and patrolling.

The system's analytics and storage improved data management. They gave the bank insights into vehicle traffic. This helped optimize operations and anticipate future security needs.

Conclusion

This top bank's use of an AI number plate recognition system is a success. It modernized its vehicle access control. The bank automated the ID and verification process. This improved security, efficiency, and the experience for employees and visitors.

The system's link with the bank's control room allowed for seamless monitoring and data management. It enabled a quick response to security events. This made the system a powerful tool in the bank's security strategy. As AI technology advances, solutions like these will become vital. They will enhance access control and security in various industries.

High-Resolution Image Capture

The system is equipped with high-resolution cameras strategically placed along the conveyor belt. These cameras capture detailed images of the vehicle's surface from multiple angles. This ensures full coverage.

Real-Time Image Processing

The AI system immediately processes the captured images. It uses advanced algorithms to spot any texture changes. The AI is trained on a vast dataset of vehicle images. It can now tell minor cosmetic flaws from major defects.

Defect Classification

Once a defect is detected, the AI system classifies it as either a dent or a scratch. The classification process is crucial. It decides the next steps in the production line. A minor scratch might be fixed later. A dent needs immediate attention.

Automated Reporting and Alerts

The system is integrated with the manufacturing unit's central control system. When a defect is found, an automated report is generated. It details the defect's nature and location. Alerts are sent to the relevant personnel, allowing for quick action without disrupting production.

Continuous Learning and Improvement

The AI system is designed to improve over time. As it processes more images and finds more defects, it keeps refining its algorithms. It becomes better at detecting even the subtlest flaws.

Outcome

The AI-based dent and scratch detection system greatly improved vehicle manufacturing.

Enhanced Quality Control

The AI system was more consistent and accurate than manual inspections. Every vehicle that passed through the line faced the same, rigorous checks. These checks ensured that defects were found early.

Reduced Manual Inspection Time

Automating defect detection cut the time spent on manual inspections. It sped up production. Vehicles could move through quality control faster.

Improved Defect Detection Accuracy

With the AI system, the accuracy of defect detection improved significantly. The system found defects that human inspectors might have missed. This was especially true for small defects in hard-to-see areas of the vehicle.

Cost Savings

Cost savings for the manufacturing unit came from two things. First, a reduction in manual inspection time. Second, the early detection of defects. Identifying defects earlier in production minimized costly rework.

The AI dent and scratch detection system greatly improved the factory. It improved both efficiency and product quality. This case study shows that AI can revolutionize manufacturing. It can set new standards for quality control in the automotive industry.